Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

+86-523-86984777

Brand: GX

Supply Type: Make-To-Order

Material: 100% Polypropylene

Use: Home Textile

Place Of Origin: China

Thickness : Medium Weight

Technics: Nonwoven

Type: Filter Fabric

Nonwoven Technics: Spun-Bonded

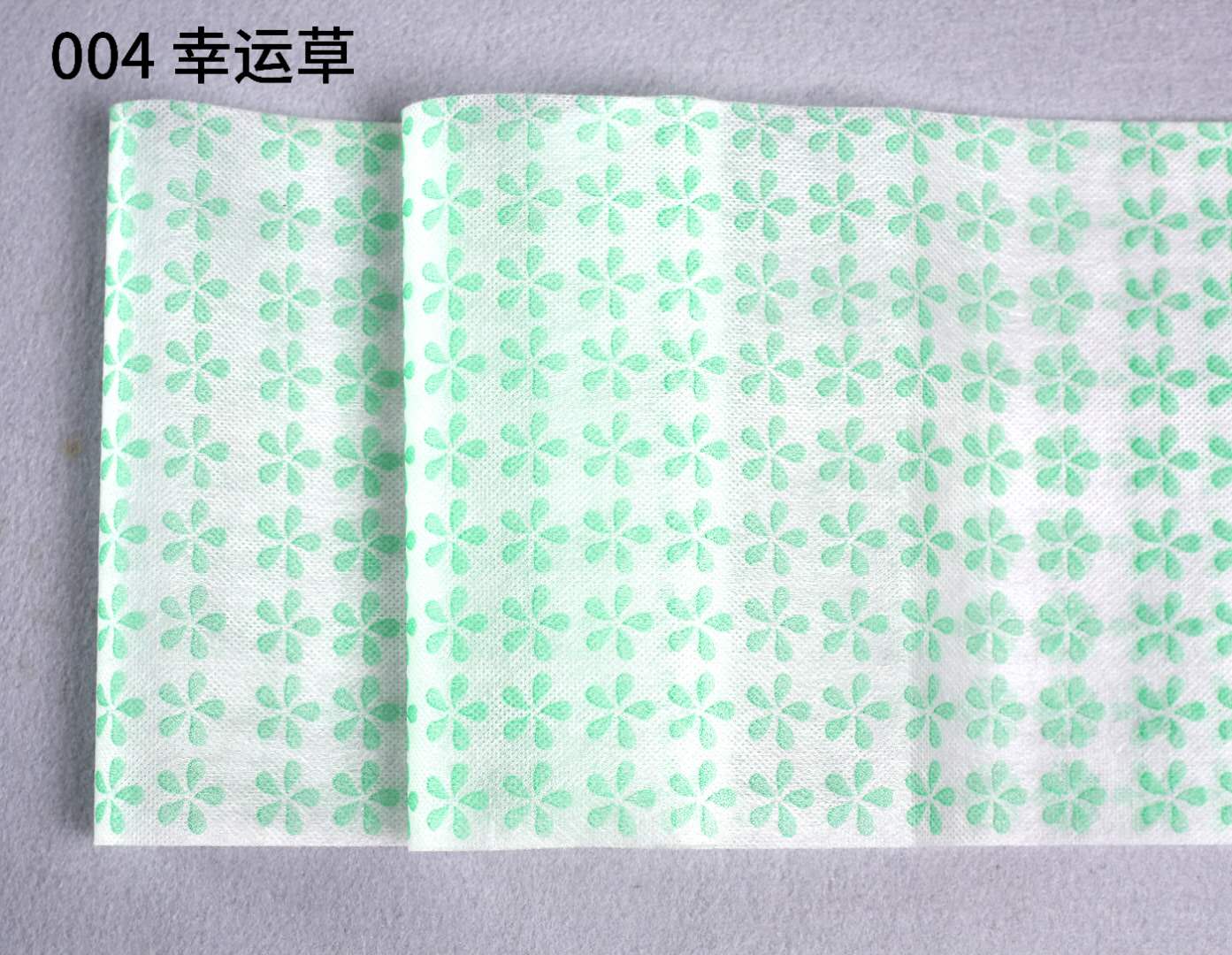

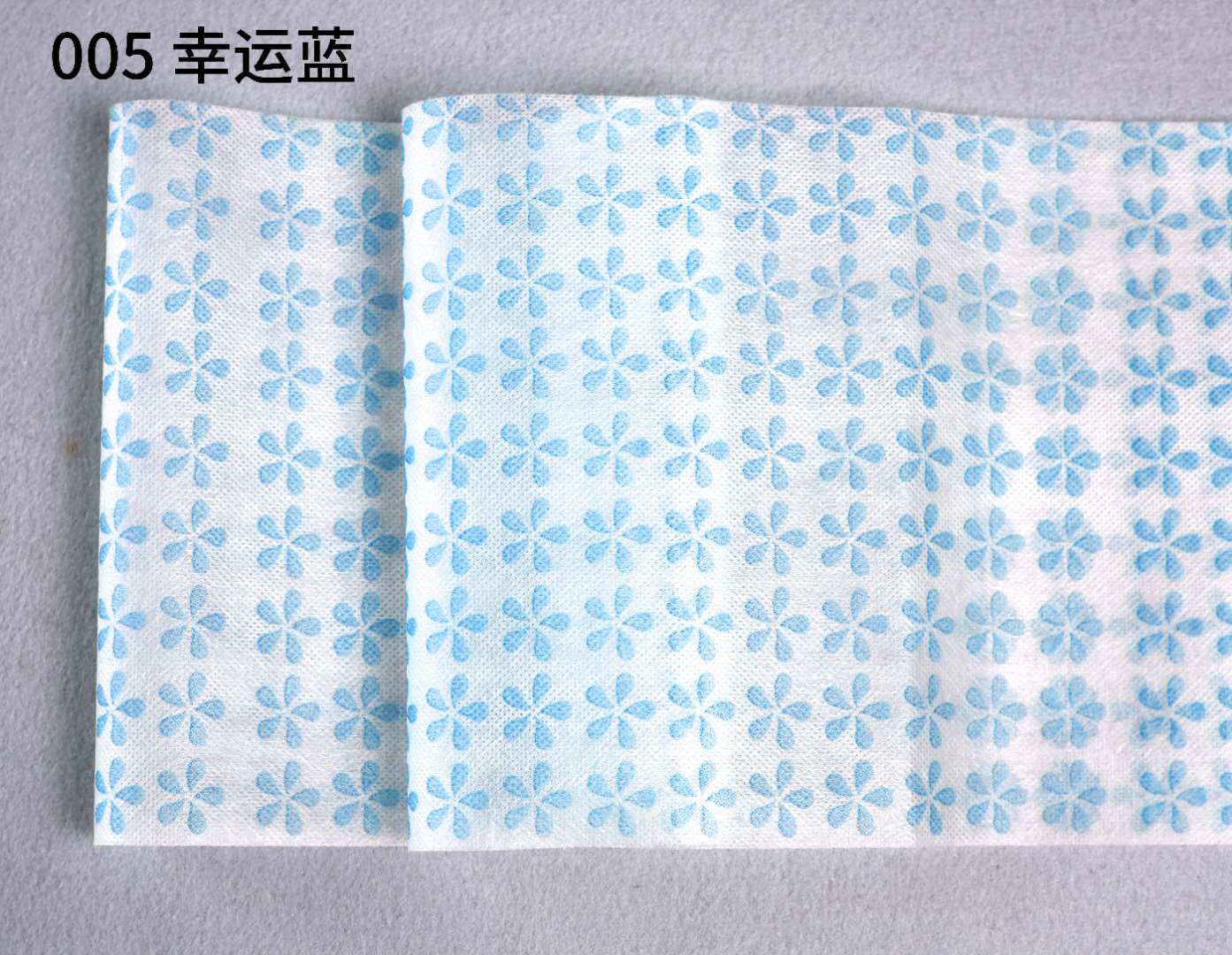

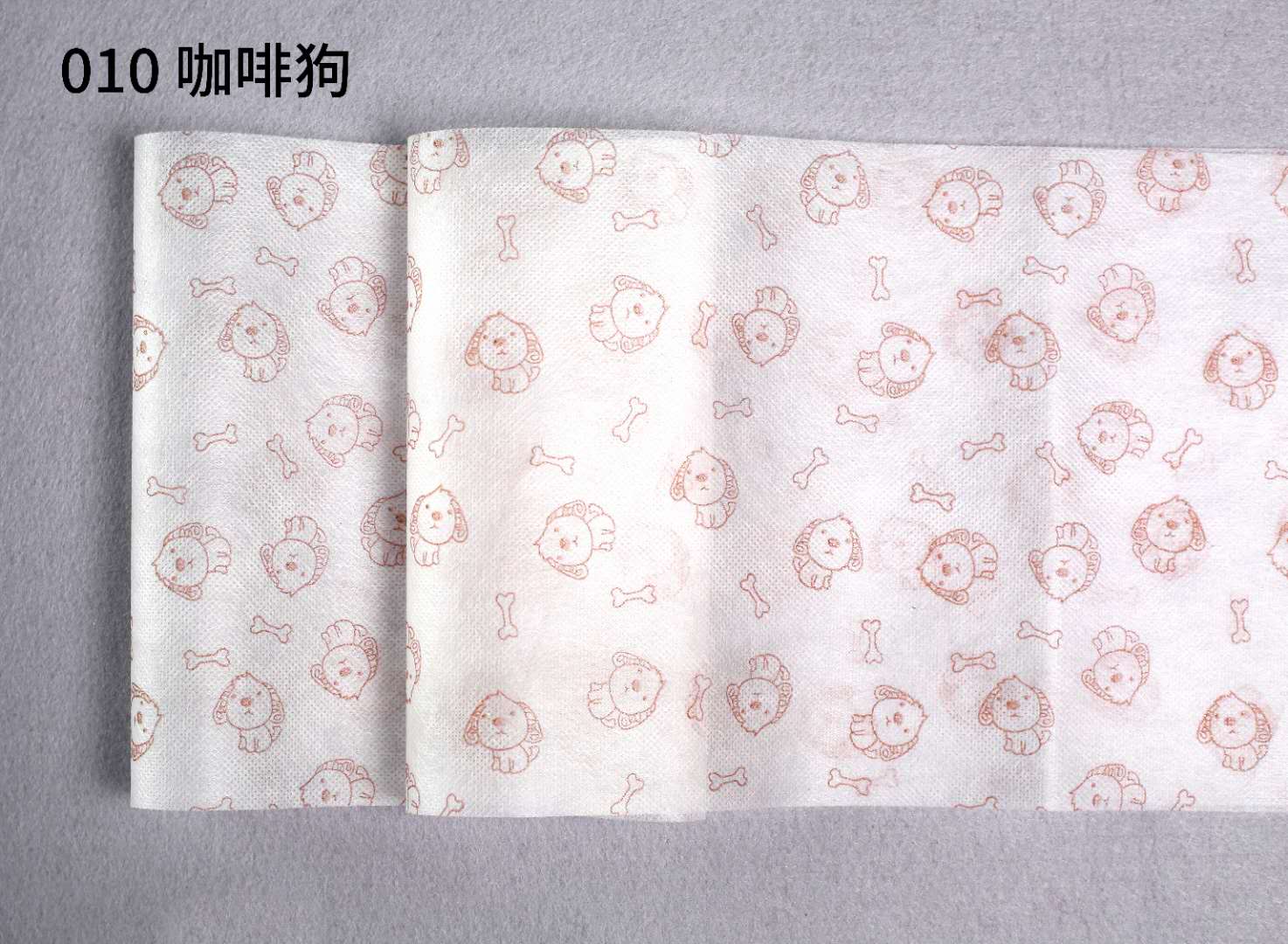

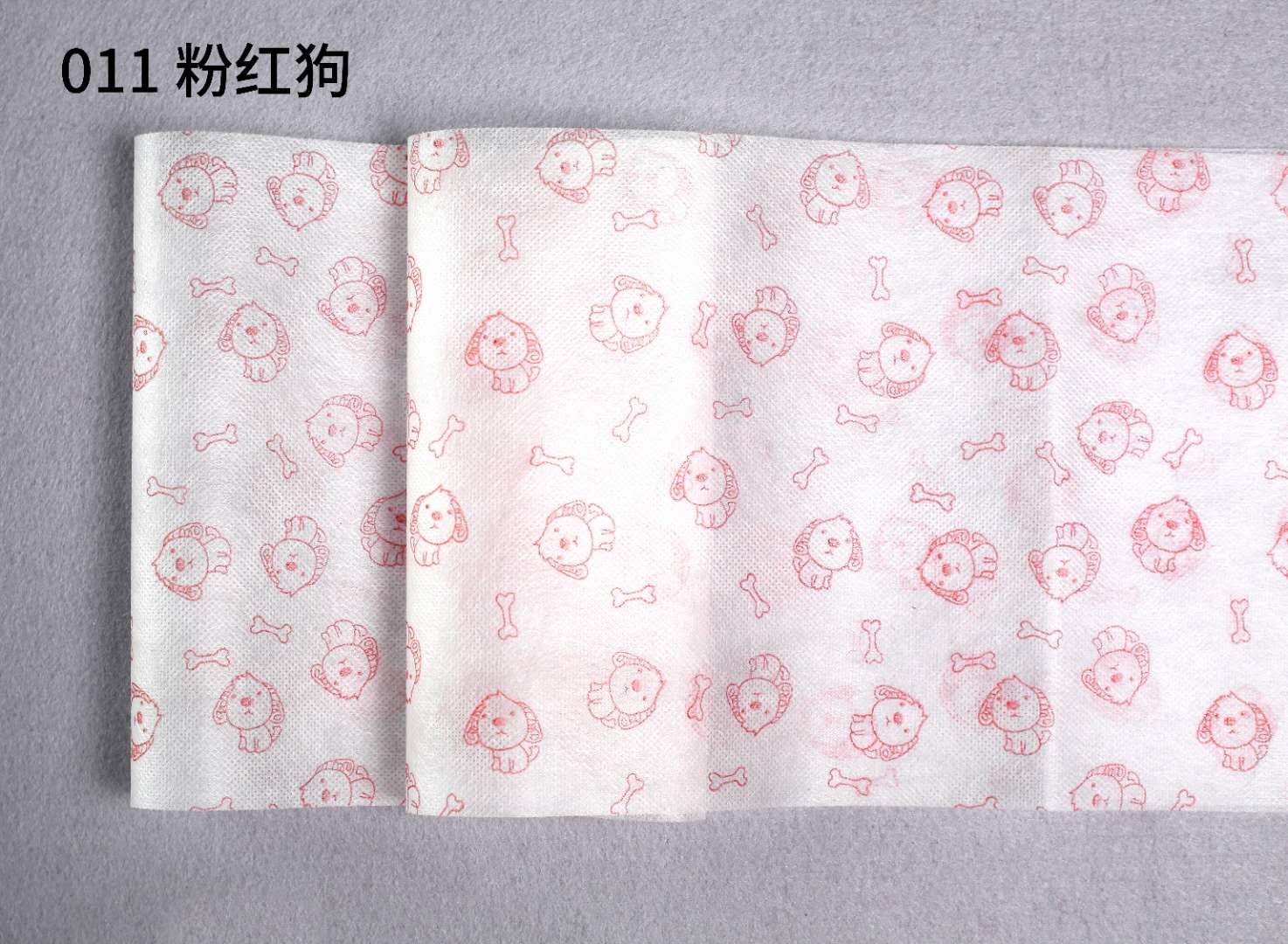

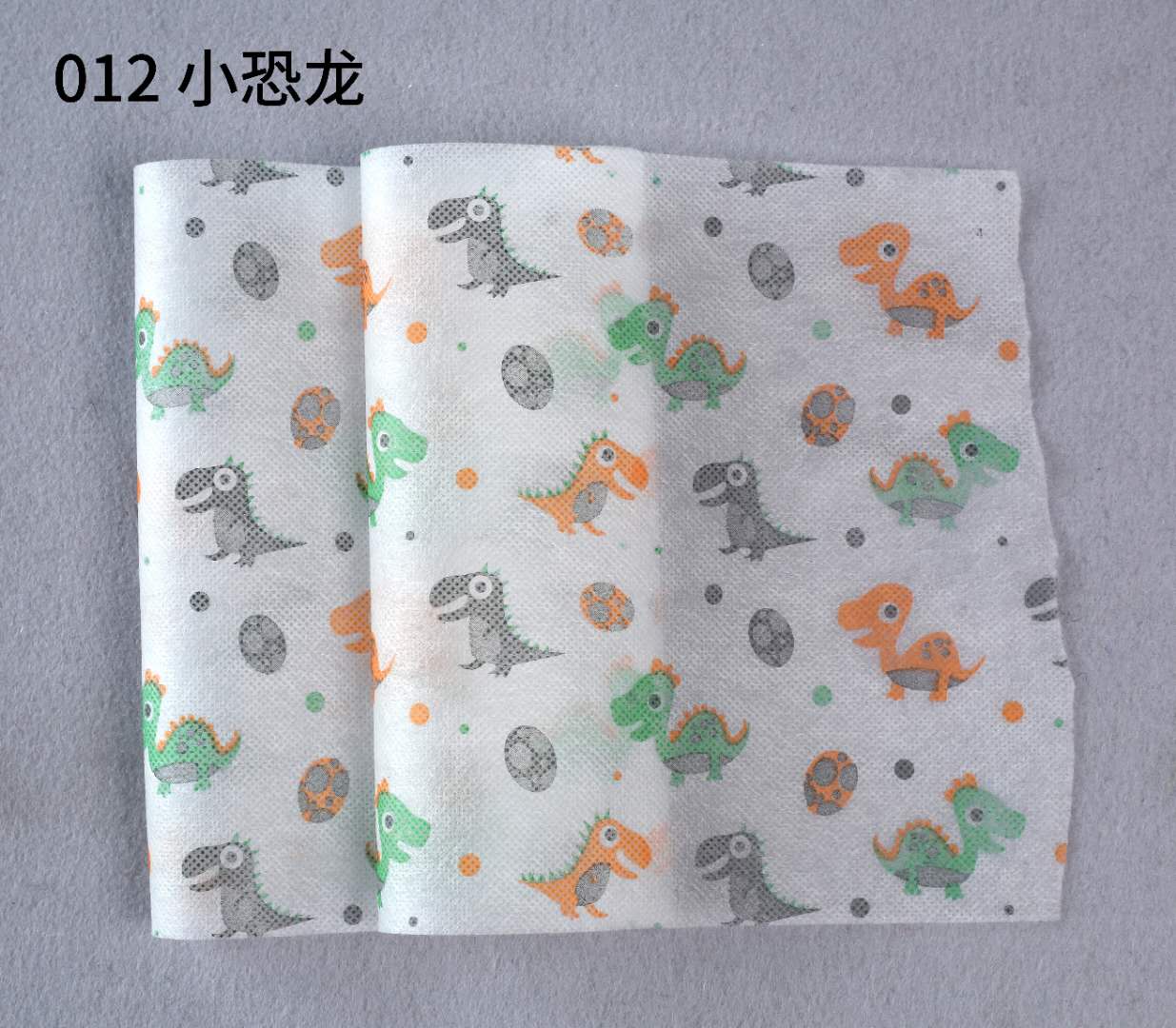

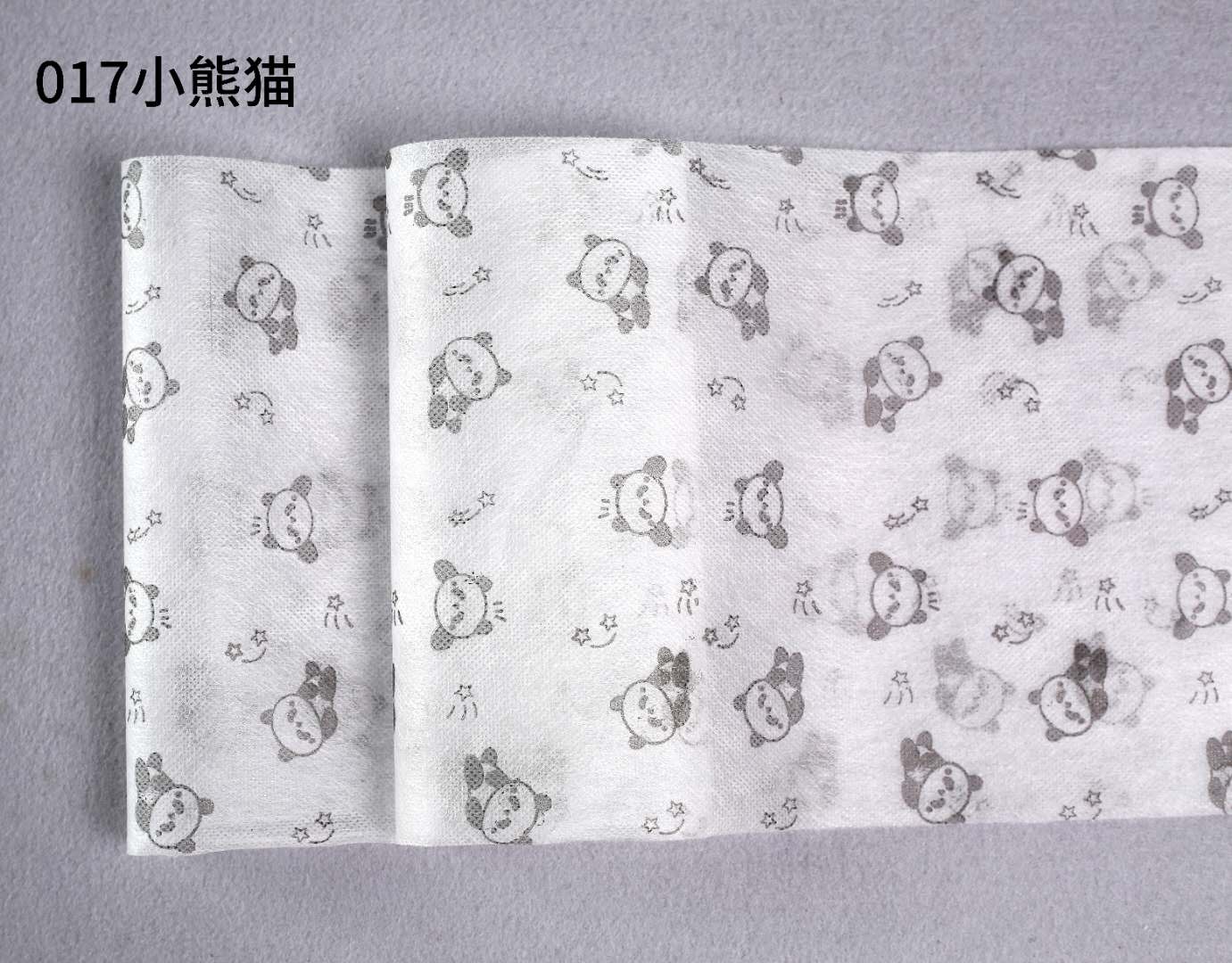

Pattern: Dyed

Feature: Waterproof, Breathable, Anti-Static, Tear-Resistant

Brand Name: Gaoxin

Style: Plain

Width: 15-150cm

Weight: 20-100g

Packaging: 1000m ----1500m/roll Weaving bag

Productivity: 70000m for one day

Place of Origin: Jiangsu,China

Certificate: ISO9000

Printed Nonwoven Fabric is moisture-proof, breathable, flexible, lightweight, flame-retardant, non-toxic, inexpensive, and recyclable. It can be used in industries such as sound insulation, heat insulation, electric heating plates, masks, clothing, medical treatment, and filling materials.

Advantages:

1. Printed Interlining Non Woven is lightweight: polypropylene resin is used as the main raw material, with a specific gravity of 0.9, which is only 3/5 of cotton, soft and feels good.

2. Printed non-woven fabric is soft: it is made of fine fibers (2-3D) lightly hot-melt bonded, and the finished product has moderate softness and is very comfortable to wear.

3. Printed Non Woven Interlining Fabric is waterproof and breathable: polypropylene slices do not absorb water, the moisture content is 0, the finished product has good waterproofness, is composed of 100% fibers, has good porosity, good breathability, the cloth surface is dry and easy to wash.

4. Printed non-woven fabric purifies the air and uses the advantages of small pores to prevent bacteria and viruses.

5. Printed non-woven fabrics are non-toxic and non-irritating: The product is produced with FDA food raw materials, does not contain other chemical ingredients, has stable performance, is non-toxic and tasteless, and does not irritate the skin.

6. Printed non-woven fabrics are antibacterial and chemically resistant: Polypropylene is a chemically blunt substance, not moth-proof, and can isolate bacteria and insects in the liquid. Antibacterial and alkali-resistant, the strength of the finished product will not be affected by corrosion.

7. Printed non-woven fabrics are antibacterial, the product does not mold when pumping water, isolates bacteria and insects in the liquid, and prevents fungal erosion.

8. The physical properties of printed non-woven fabrics are very good. The strength of the product made by direct web laying and heat bonding of polypropylene spinning is better than that of general short fiber products, the strength is non-directional, and the longitudinal and transverse strength is similar.

9. Most of the non-woven fabrics used in environmental protection are made of polypropylene, while the raw materials of plastic bags are polyethylene. The two substances have similar names, but their chemical structures are very different. The chemical molecular structure of polyethylene is quite stable and difficult to decompose. A plastic bag takes 300 years to decompose. The chemical structure of polypropylene is not strong, and the molecular chains are easily broken. It can be effectively decomposed and enter the next environmental cycle from a non-toxic form. Non-woven shopping bags can be completely decomposed within 90 days and can be reused more than 10 times. The pollution to the environment after scrapping is only 10% of that of plastic bags.

Product Categories : Activated Carbon Nonwoven > Face Mask Activated Carbon Nonwoven

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.